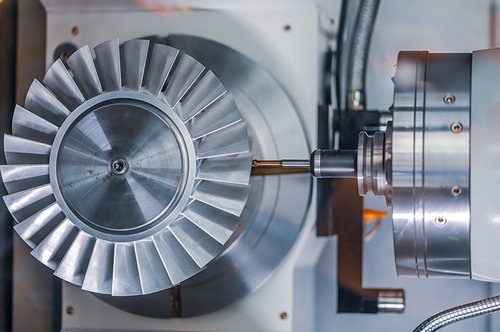

Turning-Milling Compound Machining

Turn-milling compound machine tool is the fastest growing and most widely used CNC equipment among compound processing machine tools. The compounding of machine tools is one of the important directions in the development of machine tools.

CYCOSPRAY has advanced turning and milling compound machining centers. CYCOSPRAY dedicated in perfecting for high precision parts with complex geometries, and our composite manufacturing process

- Tight Tolerance of Parts

- Fast Production & Delivery

- Professional Team Support

- Advanced Equipment

- Nearly Every Materials

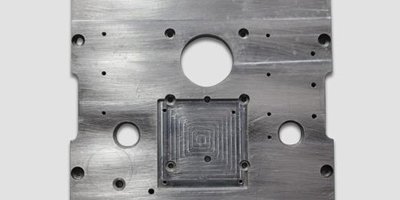

Our CNC Machining Service Capabilities

Count on our on-demand CNC machining services for your parts on time, every time. Achieve outstanding results with our CNC milling and turning capabilities in as fast as five days.

CNC Precision Machining

CYCOSPRAY provides CNC precision machining services for custom CNC parts of any specification, in any material.

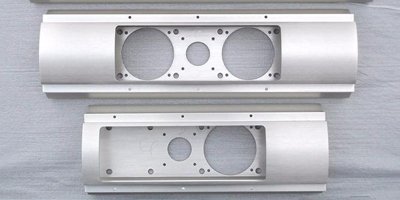

CNC Milling Service

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC Turning Service

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Turning-Milling Compound Machining Service

Combination of CNC lathe and machining center.

Various Materials Can CYCOSPRAY Providing for You

Turning-Milling Compound Machining suits for parts that require high precision, accuracy and repeatability, parts with complex geometry, good surface finish and high tolerances, or parts made of a variety of materials, including metal, plastic and composite materials.

Following are some main kinds of materials that we turning-milling composite are well-suited for machining:

Metals including:

- Steel: Carbon steel, stainless steel, tool steel, alloy steel, etc.

- Aluminum: Aluminum alloys, such as 6061, 7075, and cast aluminum.

- Brass: Common brass alloys, such as C360, C464, and C687.

- Copper: Pure copper and copper alloys like bronze and brass.

- Titanium: Titanium and its alloys, known for their high strength-to-weight ratio.

- Nickel-based alloys: Inconel, Hastelloy, Monel, and other heat-resistant alloys.

- Precious metals: Gold, silver, and platinum alloys.

Plastics including:

- Acrylic (PMMA): Transparent and lightweight material used in displays and signs.

- Nylon: Known for its toughness, low friction, and excellent wear resistance.

- Polycarbonate (PC): Impact-resistant material commonly used in automotive and electronic applications.

- Polyethylene (PE): Versatile plastic with good chemical resistance and low friction.

- Polypropylene (PP): Lightweight and chemical-resistant material.

- PEEK: High-performance thermoplastic with excellent mechanical properties.

- PVC: Rigid plastic used in construction, electrical insulation, and piping.

But our limits are far from that, please contact with us if you have any materials needs besides up mention, we’ll provides the best composite machining services to suit your requirements.

CYCOSPRAY Machining Surface Finishes Services

Surface Finishes can not only improve the appearance of CNC machined parts, but also increase the functionality of the internal parts, wear resistance and corrosion resistance, and extend the service life of the parts.

This finishing option has the shortest turnaround time. Parts have visible tool marks as well as potentially sharp edges and burrs that can be removed upon request.

Smooth machining is similar to last "As machined" finish, but machine marks are less obvious. Parts are machined at a lower feed speed without manual polishing.

The method of applying the grinding brush to the surface, it produces a uniform surface, but visible lines is its feature.

Materials: ABS,Aluminum,Brass,Stainless Steel,Steel

Parts are bead blasted with glass beads to produce a uniform grainy texture and reduce processing marks.

Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

The vibrating medium rolls over the machined part to remove sharp edges and burrs, and the roll can be used to remove machine marks on the outer surface. Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

Bead blasting followed by anodizing (type II) matte surface finishing to create a uniform matte finish, the colors are naturally matte. It is ideal for improving corrosion resistance and aesthetics.

The material is brushed to form uniform oriented particles and then anodized to make it shiny. It forms a hard, wear-resistant oxide layer on the surface of the part to enhance its durability and corrosion resistance.

By anodizing the surface of a machined part for CNC milling, CNC turning, or 2-axis, 3-axis, or 5-axis CNC machining, a thick and durable oxide layer can be formed.

Through a chemical conversion process, metals such as aluminum and magnesium are coated with a thin protective film that gives excellent corrosion resistance and enhances the adhesion of subsequent coatings on CNC machined parts.

What is Turning-Milling Compound Machining?

As the name suggests, CNC turning-milling compound machining is a composite machine tool that includes all the functional characteristics of CNC lathes and CNC milling machines.

The purpose of composition is to make a machine tool that assembled with multiple functions, including turning-milling combination, turning-milling-grinding, milling-grinding compound, it can complete multiple tasks at one time and improve the processing efficiency and accuracy.

Why Choose CYCOSPRAY Machining

- Professional Team Support: We have a team of professional engineers and technicians to provide professional support 24/7 to help you solve your problems.

- Strictly Quality Control: We’re following strict quality control system to ensure quality prototypes and production parts.

- Advanced Equipment: We have the same manufacturing and testing equipment. Your parts will be manufactured and tested using our state-of-the-art equipment.

- Fast Turnaround: We follow a strict quality control system to ensure the manufacture of quality prototypes and production parts.

Gallery of CNC Machining Workshop