CNC Precision Machining

CYCOSPRAY provides CNC precision machining services for custom CNC parts of any specification, in any material.

Get instant CNC quotes today, and order your custom metal and plastic parts.

- High Precision: Standard dimensional tolerance of ±0.005mm(0.0002in)

- Various CNC machines: 3-axis, 4-axis, and 5-axis CNC machines

- Various Work Techniques: CNC milling, CNC turning, wire EDM, etc.

- Get your products and parts ready in as fast as 24 hours

- Certifications: ISO9001:2015, IATF 16949:2016

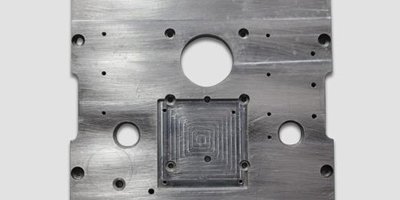

Our CNC Precision Machining Capabilities

Count on our on-demand CNC precision machining services for your parts on time, every time. Achieve outstanding results with our CNC milling and turning capabilities in as fast as five days.

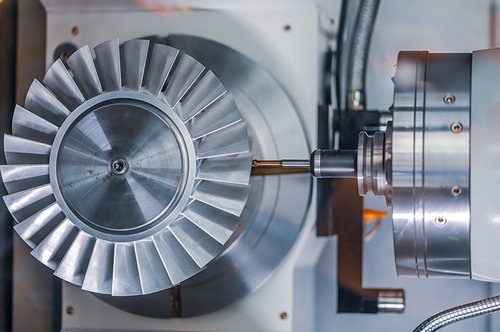

CNC Milling Service

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC Turning Service

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Turning-Milling Compound Machining Service

Combination of CNC lathe and machining center.

CNC Precision Machining

40 sets of CNC, more than 200 lathes and other machining equipment, 24-hour shifts, two physical factories

CNC Precision Machining Materials

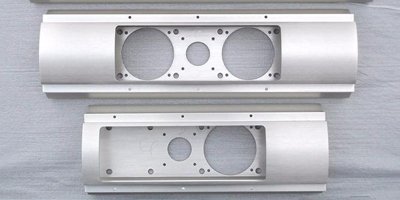

- Aluminum: 2024, 5083, 6061, 6063, 7050, 7075, etc.

- Alloy: Brass 360, 101 copper, 110 copper, 932 bronze, zinc, etc.

- Titanium: Grade 2, Grade 5, etc.

- Stainless steel: 303, 304, 410, 17-4, 2205 duplex, 440C, 420, 316, 904L, etc.

- Steel: 4140, 4130, A36, 1018, etc.

- Plastics: POM (Delrin), ABS, HDPE, nylon, PLA, PC, PEEK, PMMA, PP, PTFE, etc.

CNC Precision Machining Application Industry

- Mechanical Parts Category: Fastener, Motor shaft, Empty metal cans, Conductive pins, Connector joint, Shaft sleeve, Pneumatic fitting, Hydraulic fitting, Hose joint pipe coupler, Screws(Rivet, Bolt, Nut), Eccentric(hollow) shaft

- Military & Defence industry: Airframe Parts, Consumables, Expendables, Avionics / Instruments, Engine Components, Rotables

- Medical and Dental Instruments: Production tooling components, Packaging accessories, Processing machinery replacement and spare parts, R&D fixtures, Testing parts, Analysis fitting

- Automobile Industry: Low pass filter shaft, Hydraulic valve, Valve housing, Sensor Housing, Pressure sensor housing, Temperature sensor housing, Pipe Joint, Throttle control shaft, Sensor metal shell

- Aerospace Industry: Fastener, Connector joint, Screw, Shaft, Eccentric hollow shaft, Pin

- Electronics Category: Metal Housing used for earphone, Aluminum pipe/tube used for tattoo and e-cigarette, Nozzle used for Shisha, Contact pins, Conductive Pins, Pivot pintle, Probes, Bushes, Test tooling

- Hunting & Fishing Industry: Blade ferrule, Insert, Insert Footer

- Other CNC Turning Application Industries

CYCOSPRAY Machining Surface Finishes Services

Surface Finishes can not only improve the appearance of CNC machined parts, but also increase the functionality of the internal parts, wear resistance and corrosion resistance, and extend the service life of the parts.

This finishing option has the shortest turnaround time. Parts have visible tool marks as well as potentially sharp edges and burrs that can be removed upon request.

Smooth machining is similar to last "As machined" finish, but machine marks are less obvious. Parts are machined at a lower feed speed without manual polishing.

The method of applying the grinding brush to the surface, it produces a uniform surface, but visible lines is its feature.

Materials: ABS,Aluminum,Brass,Stainless Steel,Steel

Parts are bead blasted with glass beads to produce a uniform grainy texture and reduce processing marks.

Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

The vibrating medium rolls over the machined part to remove sharp edges and burrs, and the roll can be used to remove machine marks on the outer surface. Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

Bead blasting followed by anodizing (type II) matte surface finishing to create a uniform matte finish, the colors are naturally matte. It is ideal for improving corrosion resistance and aesthetics.

The material is brushed to form uniform oriented particles and then anodized to make it shiny. It forms a hard, wear-resistant oxide layer on the surface of the part to enhance its durability and corrosion resistance.

By anodizing the surface of a machined part for CNC milling, CNC turning, or 2-axis, 3-axis, or 5-axis CNC machining, a thick and durable oxide layer can be formed.

Through a chemical conversion process, metals such as aluminum and magnesium are coated with a thin protective film that gives excellent corrosion resistance and enhances the adhesion of subsequent coatings on CNC machined parts.

Why CYCOSPRAY CNC precision machining?

- 23 years of industry experience, mature quotation system and technical support, multiple sales engineers docking online quotation 15 years of CNC

- 15 years of CNC machining experience, 16 engineers with more than 10 years of experience, two physical factories

- Provide technical consultation, pre-examination of drawings, structural analysis, risk assessment, constructive design suggestions, cost analysis and other services

- More than 200 kinds of materials have been processed, and the spectrum analyzer detects the authenticity of the materials

- 21 surface treatment processes

High-precision production equipment

- 40 sets of CNC, more than 200 lathes and other machining equipment, 24-hour shifts, two physical factories

- 12 sets of 4-axis CNC machines, 8 sets of CNC with tool magazine, the maximum stroke is 2300mm

- Using dynamic milling technology, the roughing efficiency is increased by 50%

- Stable personnel, the company has nearly 300 employees, and 90% of the employees are more than 5 years old

- Business and documentary personnel are all on duty after more than 3 years of training and assessment, and special personnel will follow up

- 1-10 pieces CNC processing 1-5 days, 100-1000 pieces small batch production 7-15 days

Engineers review drawings, advanced testing equipment to ensure quality

- Engineers pre-review drawings, focus on reviewing accuracy and assembly, and formulate processing plans

- Original imported CNC processing equipment, BT spindle, smoothness Ra1.6, tolerance ±0.005mm

- Good at complex workpieces, can customize special fixtures and fixtures for projects

- Fully automatic three-coordinate detector, quadratic element, altimeter, etc. 21 kinds of testing equipment

- At least 4 full inspection procedures for each product

- Has passed ISO9001: 2015 quality system certification